| Power supply |

110-240 V, 50/60 Hz |

|---|---|

| Energy consumption |

< 10 W |

| Viscosity range |

1 to 10.000 mPas |

| Repeatability |

Deviation ± 1% for η > 10 mPas |

| Calibration |

reference oil calibration |

| Response time |

approx. 15 s |

| Frequency |

approx. 56 kHz |

| Shear rate |

approx. 3,5 *105 s-1 |

| Sensor consumption |

< 100 mW |

| Temperature range sensor |

-20°C to 120°C (optionally up to 300°C) |

| Pressure range sensor |

25 bar |

| Temperature measurement |

PT100 (4-wire technology), +/- 0,1°C |

| Data communication (computer) |

RS-232 interface |

| Dimensions electronic unit (LxWxH) |

330 x 290 x 145 mm |

| Dimensions sensor |

immersion depth 50mm, |

QVis 01/o Process Viscometer

Our QVis 01/o inline viscosimeter automates your viscosity monitoring and generates measuring results that are reproducible and documentable.

Banish flow cups and keep track of your fluid viscosity at all times!

Application

Since measurement of the dynamic viscosity with QVis is completely independent of the direction of flow, the mounting of the QVis 01/o sensor can be realized in any form of pipe, regardless of the flow conditions in it. QVis can be operated in stand-alone mode or it can be connected to your PC: a comfortable Windows software is included in the delivery to allow you to automate measuring procedures and to further process the obtained data.

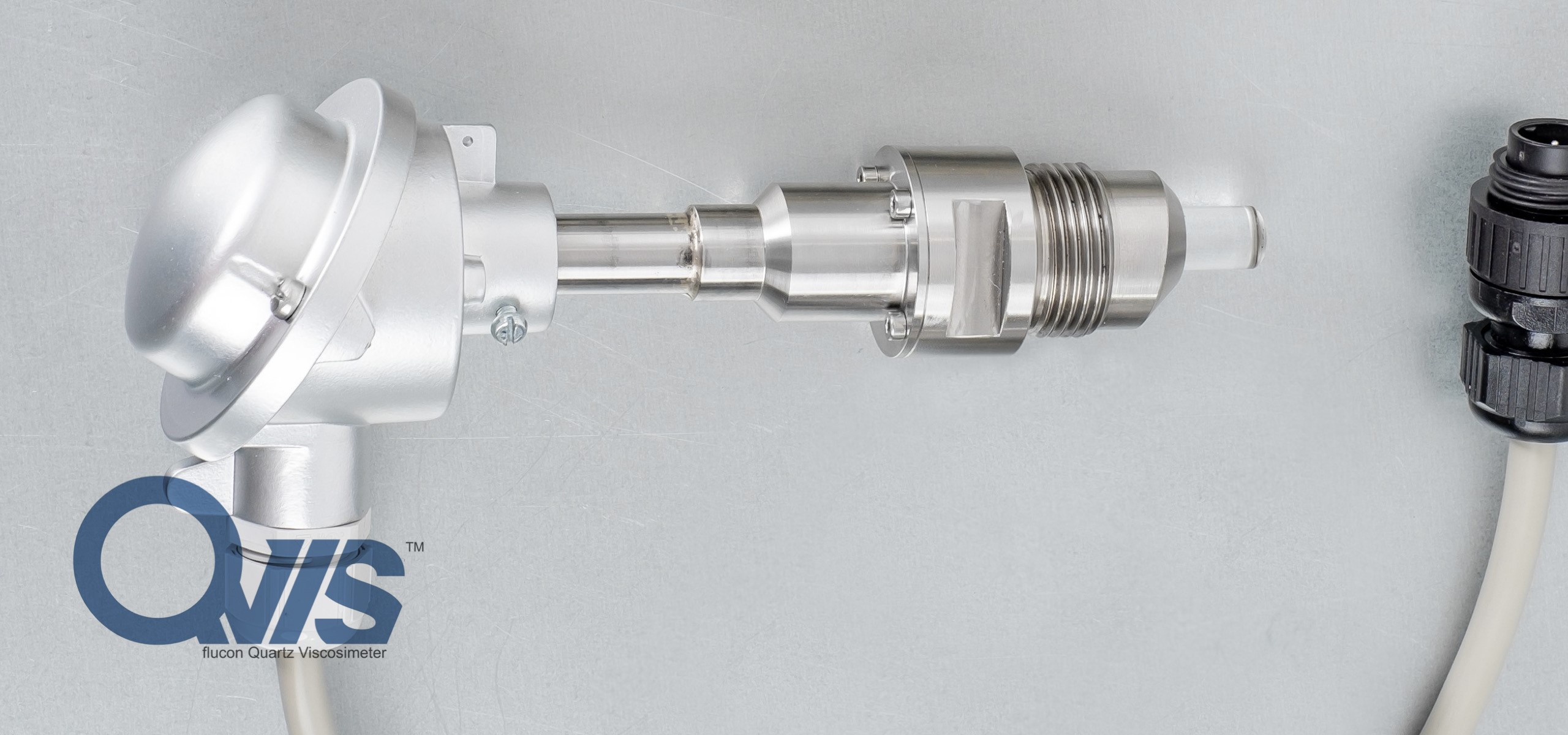

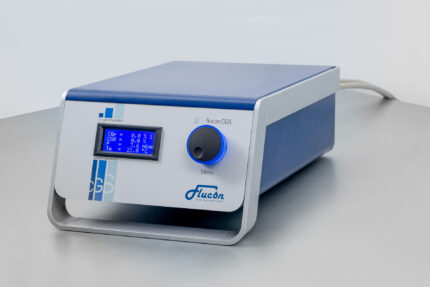

Composition

The QVis 01/o inline viscometer consists of only two components: a probe and a compact electronic unit which are connected with a flexible cable. The robust plastic housing includes an electronic control and evaluation system and can be mounted on the nearest wall or installed in your control cabinet.

The probe contains the unique SiO2 torsional tranducer and is equipped with a G 1″ screw connection to give you maximum flexibility in regard to the installation. Depending on your requirements further types of sensors (e.g. clamping-fastened sensors with a screw-cap or sensors with special thread or even flange connection) are available upon request.

Surface Tension Instruments

Surface Tension Instruments  Particle Characterization

Particle Characterization  Foam Analyzers

Foam Analyzers  High Pressure Reactors and Pilot Plants

High Pressure Reactors and Pilot Plants

Laboratory Baths and Circulators

Laboratory Baths and Circulators